We specialize in transforming manufacturing operations through systems, infrastructure, and employee mindsets, and provide strategic guidance on a wide range of manufacturing issues such as network configuration, capital productivity, and make vs. buy decision-making.

How we work

How we workOur approach to performance transformation addresses three main areas: the operating system; management infrastructure; and employee mindsets, capabilities, and behavior. We combine our knowledge of the world’s best operating systems with internationally recognized improvement programs, such as Lean, Six Sigma, and Theory of Constraints. We provide tailored solutions that allow clients to manage change dynamically—from the shop floor to the executive suite. In addition to helping implement our solutions, we mentor clients and build capabilities to sustain the changes.

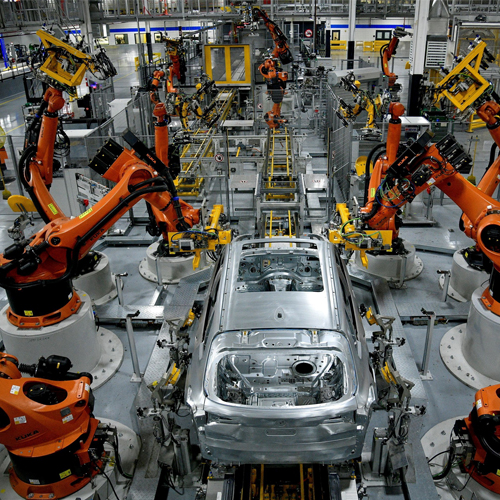

We provide strategic advice to help clients design fast, flexible, and efficient manufacturing processes that connect supply chain to factory processes, production equipment, and production systems in a seamless, customer-centric network. Examples of areas of focus include:

Our approach to performance transformation addresses three main areas: the operating system; management infrastructure; and employee mindsets, capabilities, and behavior. We combine our knowledge of the world’s best operating systems with internationally recognized improvement programs, such as Lean, Six Sigma, and Theory of Constraints. We provide tailored solutions that allow clients to manage change dynamically—from the shop floor to the executive suite. In addition to helping implement our solutions, we mentor clients and build capabilities to sustain the changes.

We provide strategic advice to help clients design fast, flexible, and efficient manufacturing processes that connect supply chain to factory processes, production equipment, and production systems in a seamless, customer-centric network. Examples of areas of focus include:

We develop best practice approaches and techniques to cover important core areas in manufacturing such as reliability, variability management, and quality, as well as on rapidly evolving current topics such as green manufacturing and IT-enabled operations.

We develop programs for capability building in a multitude of formats including boot camps, model factories, lean academies, and proprietary tools. Our energy efficient and lean model factories enable us to demonstrate manufacturing techniques and approaches in a very tangible, practical way to clients spanning all sectors. These factories facilitate hands-on experience for clients on topics such as lean capability building, change agent leadership, and integrated performance transformation.

120 W Golf Rd #100C Schaumburg, IL – 60195, USA

2050 N Plano Rd, Richardson, TX – 75082, USA

17025 Tomken Rd, Mississauga, ON – L5S 1R6, Canada

1111 Bd Dr.-Frederik-Philips #600 Saint-Laurent, QC – H4M 2X6, Canada